生產設備

鑄造機

D.C Caster

熔爐熔煉後的鋁錫經過線上除氣、除渣、細化後,注入冷水式鑄模中,

藉由嚴格控制溫度、速度、水流等關鍵技術來鑄造鋁扁錠。

After being online degassed,de-dross and refined,

molten aluminum is pour into casting mold with water cooling system to cast slabs with strict control of temperature,

speed, water flow and relevant key techniques.

|

|

熱軋機

Hot Rolling Mill

產出的鋁扁錠經過鉋皮機、加熱爐和四重熱軋機,

進行多道次壓軋,製成適合冷軋工藝的高品質熱軋捲。

The Slabs through scalping machine, recheating furnace and four reversing hot rolling maill,

multi-pass rolling to produce high quality hot rolling coli that suitable for cold rolling.

四重式軋機 (Four High Reversing Hot Rolling Mill) 最大壓軋寬度 1400mm。

|

|

冷軋機

N.1 Cold Rolling Mill

單向四重冷軋機可產出高品質產品。透過自動片形控制AFC和自動厚度控制AGC能保證產品質量,並提供多種規格之產品。

One set of four high non-reversing cold rolling mill to output high-quality products.

The plant automatically controls flatness and thicknrss by AFC and AGC for wide range of final products form thickness 6.0mm~0.1mm.

壓軋厚度 0.1mm 至 7.35mm,最大壓軋寬度 1400mm。

|

|

張平機

Tension Leveller

張平機具有裁邊、清洗、整平與分卷功能,並使鋁捲、片擁有良好的平坦度以及符合客戶之需求。

Function of Tension Levelling are to side trim,degrease, level,

slice and make aluminum coils and sheets with good flatness to meet customer's needs.

加工厚度 0.5mm 至 3.2 mm,最大寬度 1270mm。

|

|

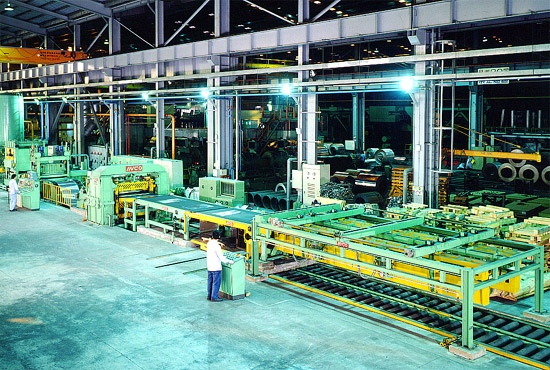

分條機

Slitting Line

按照客戶需求準確的切割產品寬度,以提供尺寸精密高、品質佳的鋁捲.

Width of product acurately slit to meet customers need and to provide high precision,

good quality Slitted aluminum coils.

分條厚度 0.2mm~ 5.0mm

寬度 15mm~1220mm

內徑 200/305/508mm

|

|

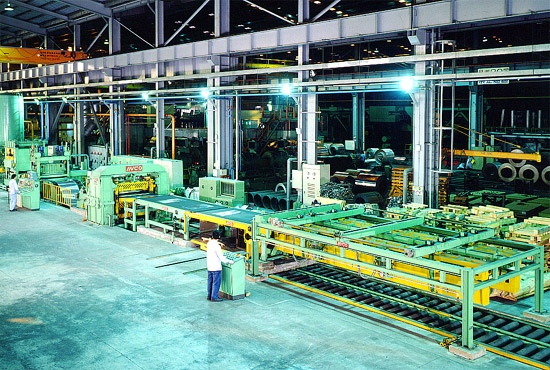

切片機

Cut To Length

經過整平後按照客戶需求準確的切割長度滿足客戶的多種需求。

After levelling, length is accurately cut to meet the various needs of customers.

切片機一套,切片長度 550mm 至 4000mm。

|

|