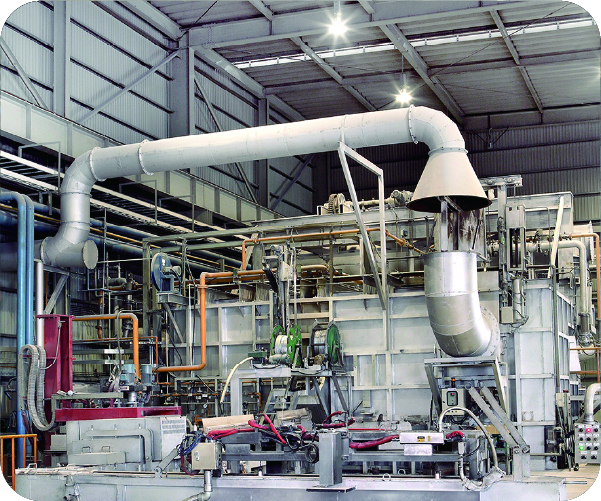

熔鑄

D.C. CASTER

After being online degassed, de-dross and refined, molten aluminum is pour into casting mold with water cooling system to cast slabs with strict control of temperature, speed, water flow and relevant key techniques.

Specifications: (width * length)

1. 3 ft(990*5000)

2. 4 ft(1270*5000)

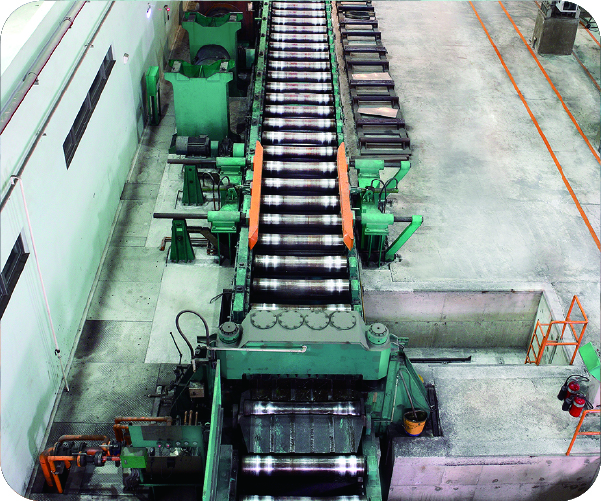

熱軋

HOT ROLLING MILL

The Slabs through scalping machine, reheating furnace and four reversing hot rolling mill,multi-pass rolling to produce high quality hot rolling coil that suitable for cold rolling.

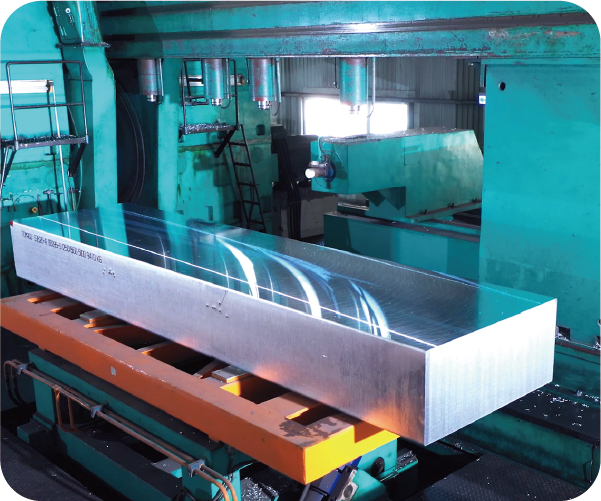

冷軋

N.1 COLD ROLLING MILL

One set of four high non-reversing cold rolling mill to output high-quality products. The plant automatically controls flatness and thickness by AFC and AGC for wide range of final products from thickness 6.0mm~0.1mm

退火

ANNEALING

During hot or cold working, the material undergoes work hardening, which increases the strength or causes processing difficulties. In order to eliminate these work hardening, heat treatment (annealing) is performed before, during or after processing to eliminate or reduce the work hardening. The processing operation can continue.

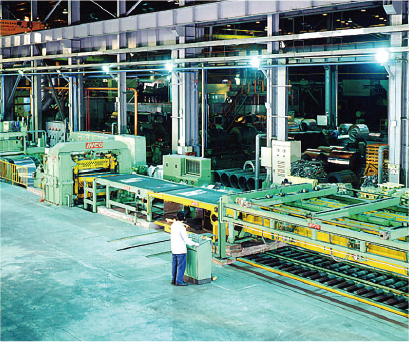

FINISHING

張力整平

TESION LEVELLER

Function of Tension Levelling are to side trim, degrease, level, slice and to make aluminum coils and sheets with good flatness to meet customer’s needs.

分條

SLITTING LINE

Width of product accurately slit to meet customer’s need and to provide high precision, good quality slitted aluminum coils.

切片

CUT TO LENGTH

After levelling, length is accurately cut to meet the various needs of customer’s.

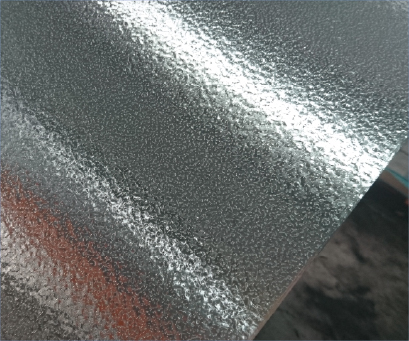

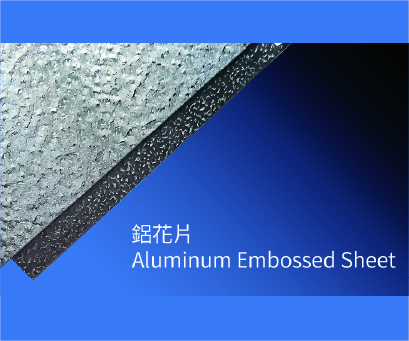

壓花

EMBOSSED

Transfer the pattern on the roller to the surface of the aluminum plate by rolling.

Thickness:0.6 mm(min)